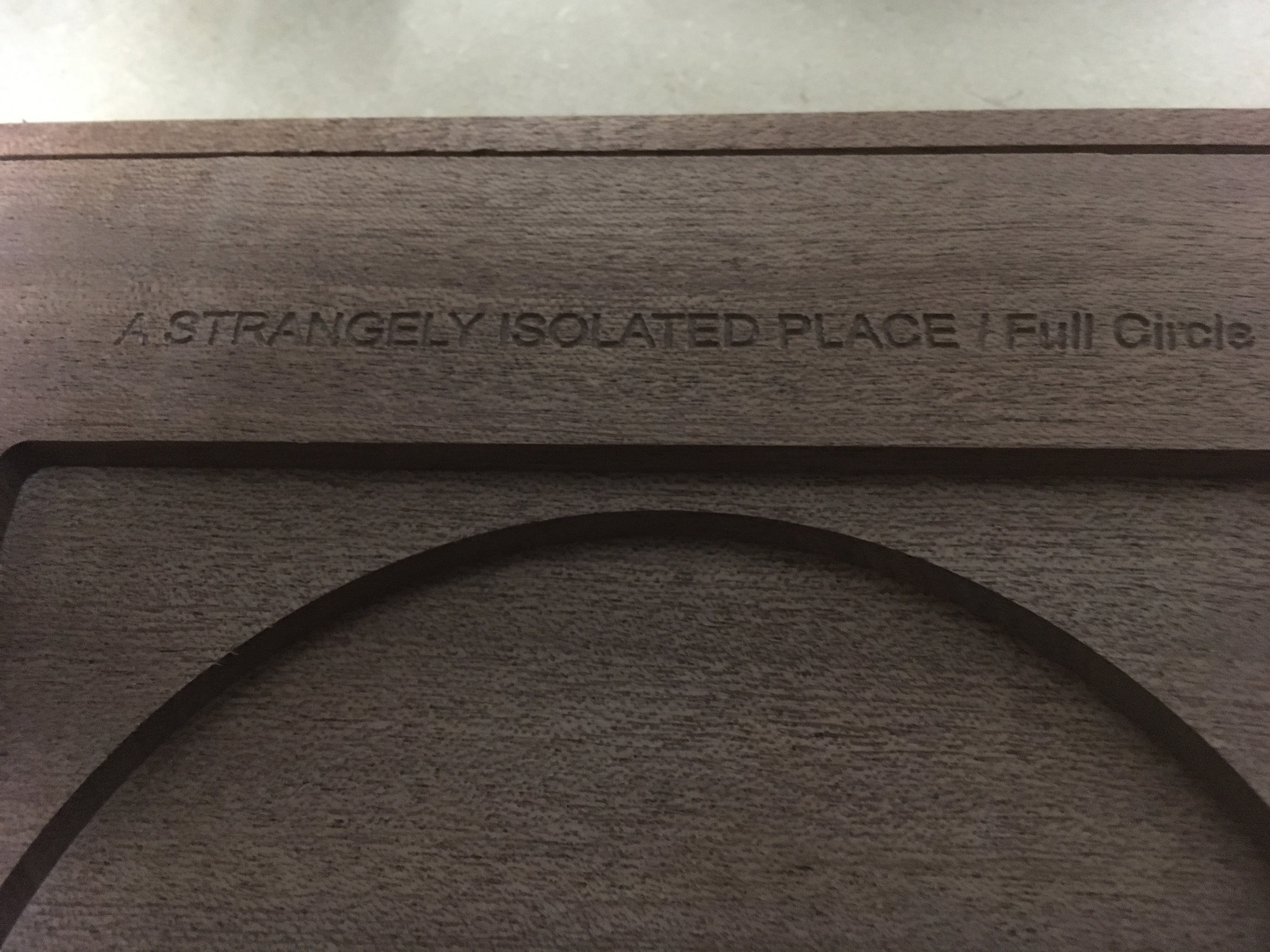

What seems to be a tradition now with any ASIP compilation (Europe, Uncharted Places and now Full Circle), we enlisted Kevin Bryce to make a limited, hand-made wooden companion to the main release.

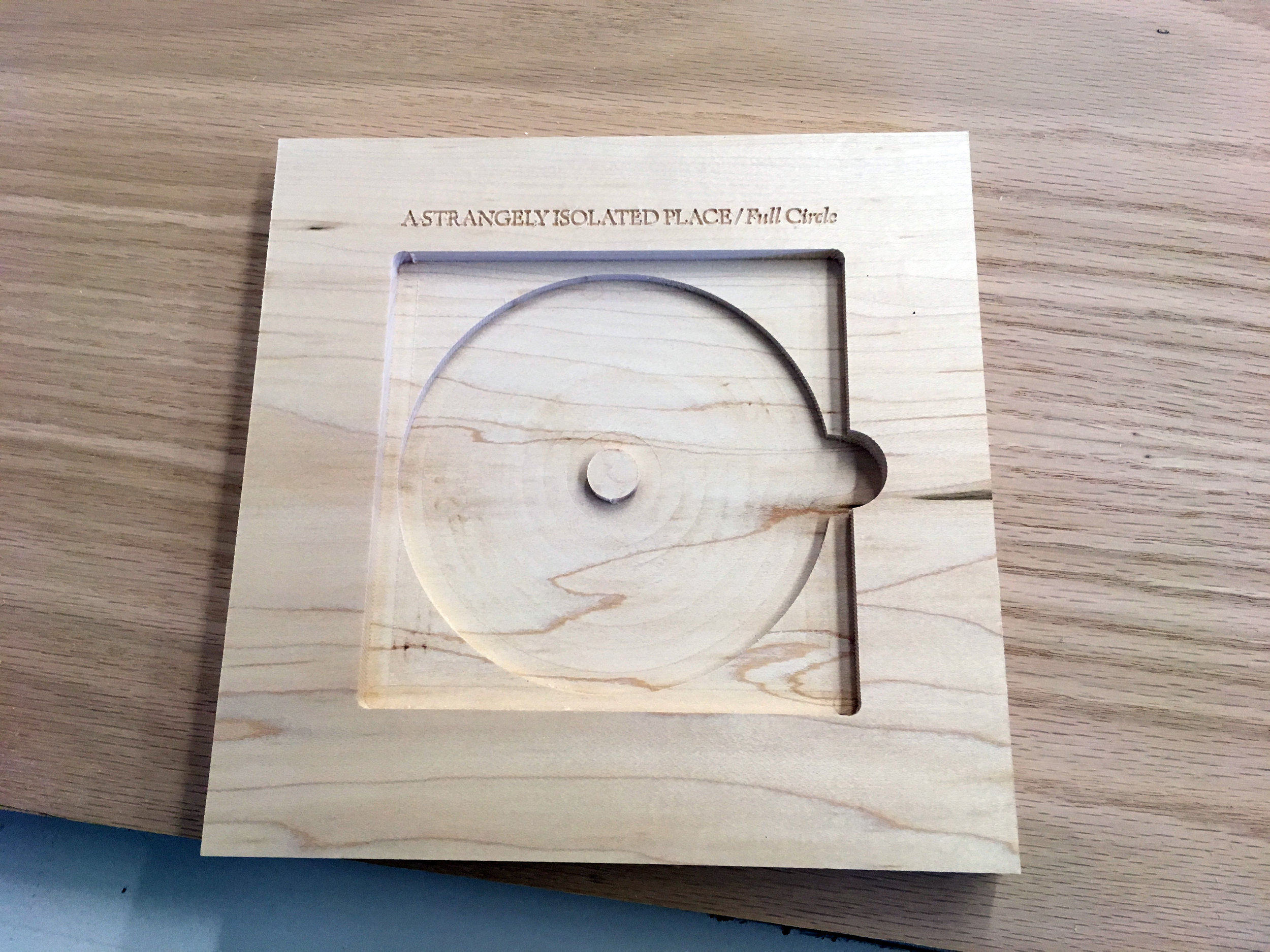

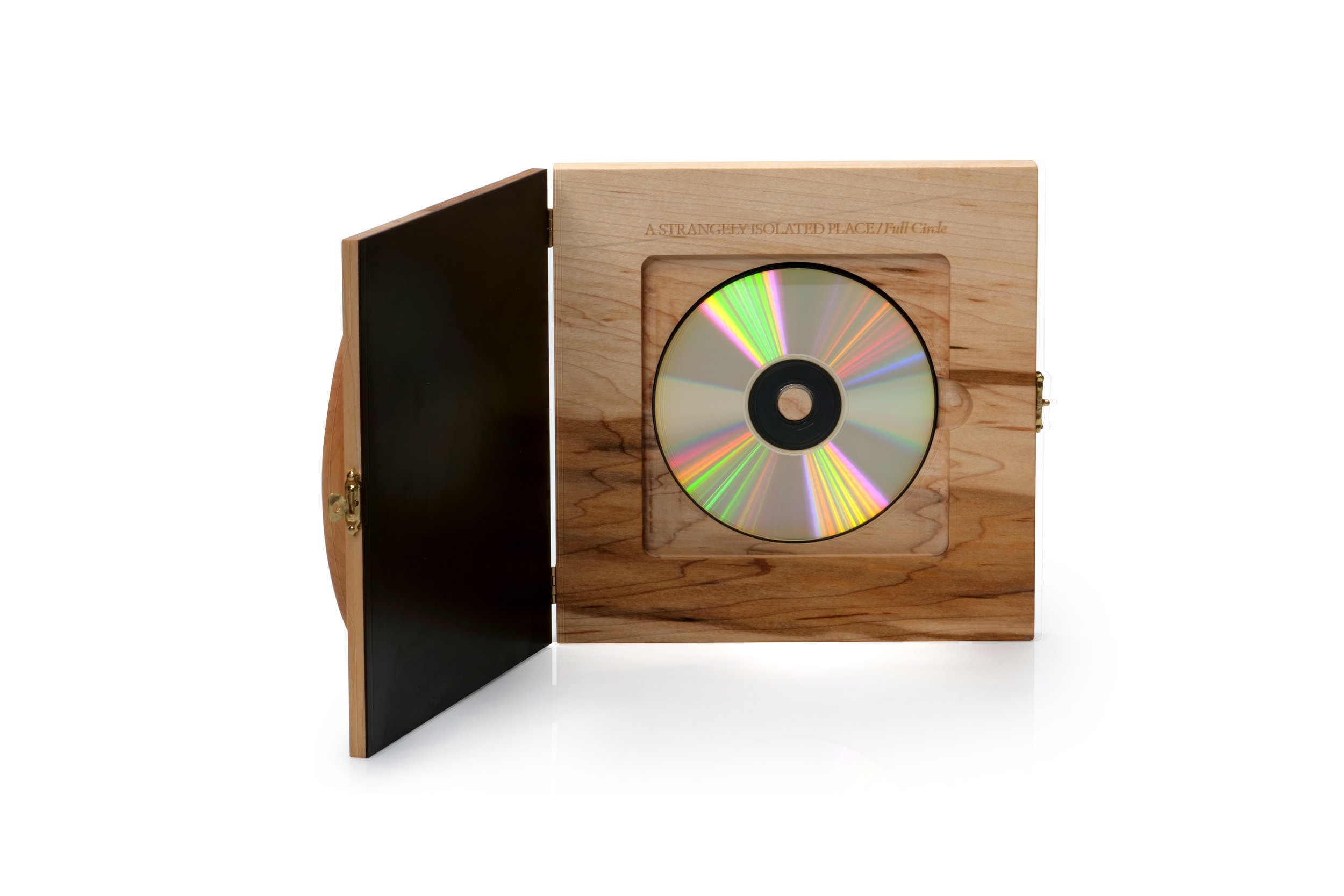

This time, Kevin made five beautiful CD cases, which were modeled off the main Full Circle artwork by Mario Morales. The vinyl artwork was a 3D take on the ASIP logo, and Kevin decided to take the 3D files used to generate the design, and make a real-life wooden version. Like everything Kevin has done for us (the Uncharted Places CD case and the Europe Vinyl Case for example) it turned out absolutely beautiful.

Hours of craft and detail went into it, producing a prototype case which was near to spot on. All we did after the prototype version was deepen the inlay to host two CD’s and add a black felt, and title text on the inside. Then once the design and build was final, Kevin and a friend went to work sanding, detailing, and finally oiling.

The five CD cases were made available with the Full Circle vinyl release and sold out instantly back in December. Since then, Kevin has been busy finalizing them ready for delivery.

A big thank you to Kevin for the outstanding craftsmanship and effort he put into these. And thank you to the five people that snapped them up. We hope you not only enjoy them, but place them with pride for everyone to see. All profits from this, and the main Full Circle release are going to charity - The Harmony Project.

An introduction and overview of the process by Kevin Bryce, including care instructions for you lucky five owners:

This was a difficult but ultimately satisfying project. I had the idea after seeing the artwork for the Full Circle release and tried to think of a way to adapt the original design into a 3-dimensional shape. After a very long time trying to convert the original artwork I was able to get it into a workable albeit somewhat crude physical model. Next came several attempts at figuring out how to machine such a shape on a 3 axis CNC. It would have been handy to have access to a CNC lathe for this project but you have to work with the tools at hand…

I had access to a ton of hard Maple that had been used to make butcher-block style restaurant tables, so I went through several large piles of wood to select some wood that I thought would work for the project. I wanted to find wood with some unusual grain patterns, the main problem being trying to find neat looking wood with wood that would be structurally sound enough to handle being cut into the relatively thin pieces I would need.

Once I had the wood, I began testing the 3D cut file. It took some time to get the optimal balance between time spent on the CNC and a smooth workable finish. I eventually found the right balance (or so I thought) and proceeded to cut all the pieces for the project. Once I had all the pieces cut, it was just a matter of sanding it to a smooth finish. Unfortunately I hadn’t fully grasped just how hard this particular hard Maple was, so after spending more than eight hours sanding the first one, I enlisted the help of an old friend who I had worked with for years and years at a local Vancouver guitar shop.

Finally after countless hours and many profanities and promises to never use this particular strain of Maple again, we had five boxes ready for finishing.

One of the interesting side effects of this design is how the Tung Oil used to finish the wood is absorbed. Generally a box presents a uniform surface to be finished but with this being such an odd 3D shape, the different surfaces all seemed to absorb the oil at different rates, so it took several extra applications in order to give it a uniform finish.

After the oil had been applied and rubbed smooth, it was time to add the hardware. I was pretty nervous that pounding nails into such a thin piece of wood might cause it to split, but I got lucky and after pre-drilling the hinge and lock holes, I managed to get everything installed with no catastrophes.

A couple of notes about the care of these boxes: The hinges are quite small as they had to fit on the side of the two box pieces. So please be careful opening and closing the box. They will not stand up to a lot of abuse if allowed to swing open and rock back against the hinge.

The other important thing to note is that because these are solid wood pieces, they are susceptible to any drastic changes in relative humidity. The best way to care for them is to think of them as people. If they are kept in an environment that you would find uncomfortable, then they will very likely be uncomfortable as well and express that by warping in some way. The good news is if you happen to notice your box cupping or bowing, it can probably be remedied by placing it in a comfortable environment- about 40% relative humidity.